What’s at stake:

Nothing less than the fate of the earth. The semiconductor industry is a major contributor of greenhouse gases. It must clean up its act.

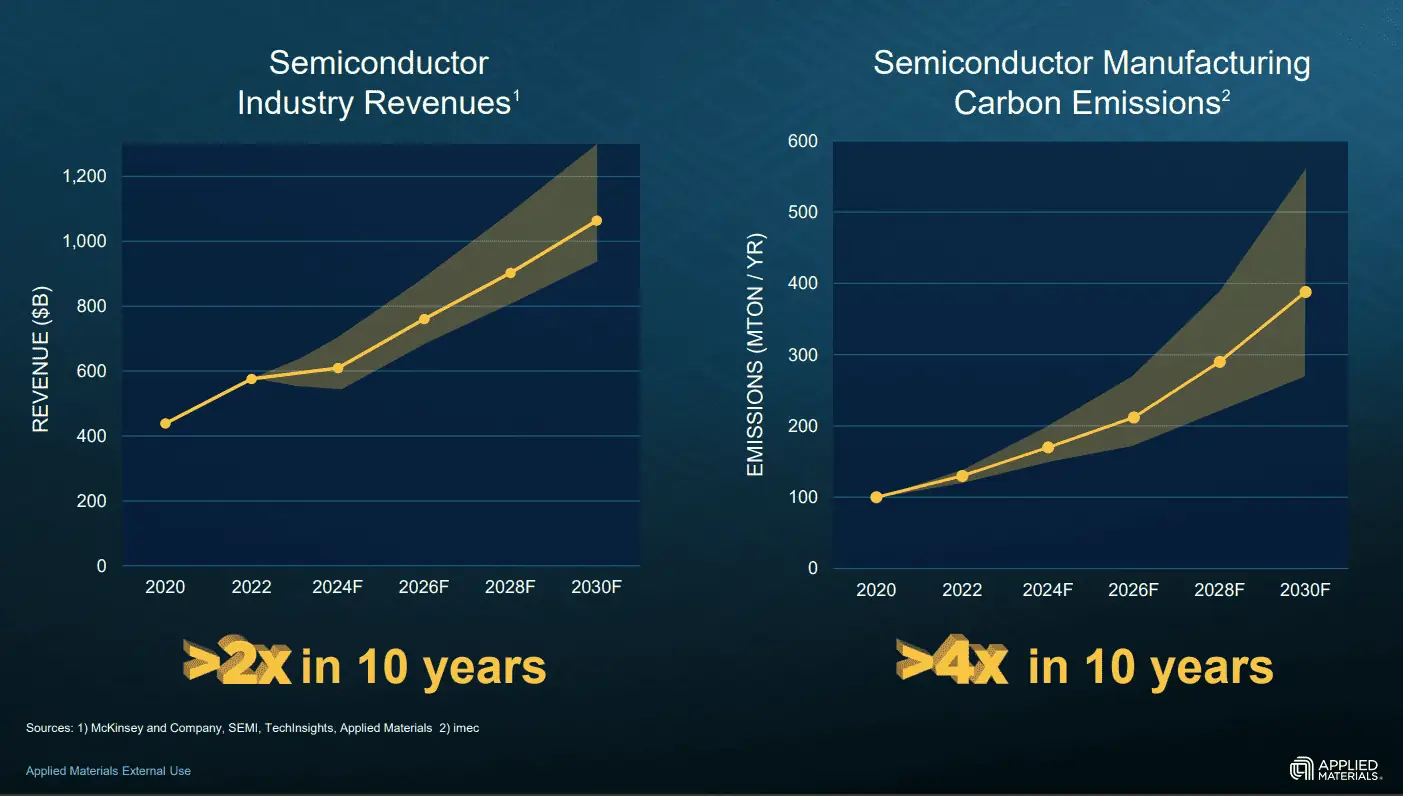

Our planet is steadily warming due to human activity. Semiconductor manufacturing, estimated to be growing at an average of 6 to 8 percent annually through 2030, is a major contributor of greenhouse gases associated with the warming of the earth’s atmosphere.

If, as projected, the global chip industry grows to $1 trillion by 2030, electricity usage on the supply and demand sides of the chip industry will soar — significantly increasing its carbon footprint. That would contribute to a far warmer and more unlivable world.

A slide from Applied Materials CEO keynote speech at Semicon West. (Sources of Semiconductor Industry Revenue are McKinsey & Co., SEMI, Techinsights, Applied Materials. The data on Semiconductor Manufacturing Carbon Emission was sourced from Imec)

Hence, the global chip industry must fundamentally change how it operates, the sooner for our planet the better. That realization has fueled a nascent sustainability movement among semiconductor manufacturers and their suppliers. The time to act is now, industry leaders understand, to achieve the industry’s ambitious Net Zero carbon emission goals.

The first step — what a chip industry group calls the “largest lever” for achieving sustainable chip manufacturing — is shifting the industry’s soaring electricity demand to renewable energy sources. That process is already underway, with key suppliers such as Applied Materials already transitioning its U.S. operations to renewables.

As part of the Ojo-Yoshida Report’s upcoming “Dig Deeper Podcast Series” with semiconductor industry leaders, we are considering ways to advance sustainable chip manufacturing. We approach the issue with the understanding that technology is a two-edged sword that can both worsen and help alleviate the climate conundrum.

The first episode, our chat wth SEMI’s Dr. Mousumi Bhat, will air on Thursday, Oct. 11. Please register here (free) to reserve your seat.

Strength in numbers

Policy makers have so far largely failed to reverse climate trends. Technologies like low-power electronics address near-term problems. But the sheer pervasiveness of semiconductor technology and the electrification of devices and automobiles means energy demand will increase exponentially. How will soaring demand be met, and by what sources? Renewables and a modern electrical grid needed to transport power to where it is needed are essential ingredients.

Ultimately, what is needed more is industry collaboration, transparency and accountability along with measurable progress. As Mousumi Bhat, sustainability leader for the industry group SEMI, told us, recent Biden administration energy efficiency initiatives are at last prompting the semiconductor industry to put its money where its attention is.

“Sustainability is a space where everybody can play — companies [and] countries can play — we can have synergies there,” says 25-year industry veteran Bhat. “It’s the power of the collective.”

SEMI launched its Semiconductor Climate Consortium in January 2023 and has recently released its baseline sustainability milestones and roadmap. The industry consortium serves as a clearinghouse and facilitator to promote collaboration. So far, nearly 90 semiconductor companies have signed on. The challenge now will be translating those ambitious goals into real progress toward sustainable manufacturing.

Sustainability is a space where everybody can play — companies [and] countries can play — we can have synergies there.

SEMI’s Mousumi Bhat

To gain adherents, proponents must also convince skeptics that long-term benefits of sustainable manufacturing outweigh the upfront costs. That will involve fundamental changes in the way chip makers and their suppliers operate. Hence, the sustainability roadmap includes three key criteria, or scopes: Scope 1 addresses reductions in direct emissions from manufacturing operations; Scope 2 covers emission related to overall energy usage; Scope 3 focuses on carbon emission across the entire semiconductor supply chain.

Among the immediate steps chip makers can take include reclaiming water, using environmentally-friendly materials and chemicals in their manufacturing processes while shifting energy consumption to renewable sources. Some chip makers are also implementing OKR (Objectives & Key Results) frameworks that tie bonuses to achieving sustainability milestones.

Meanwhile, chip designers must come up with new ways to reduce power consumption without sacrificing performance.

In a podcast interview to be posted later this month, Applied Materials CEO Gary Dickerson concludes: “I certainly believe technology will transform every industry and will create amazing benefits for the world. But we need to do that in a sustainable way.”

The challenges are daunting. A fab with 50,000 wafer starts per month is estimated to consume the energy used by a city of 100,000 residents. Sustainable manufacturing will require significant reductions in energy consumption —the Scope 2 goal mentioned above — to reduce the industry’s carbon footprint.

Concludes Dickerson: “That has to be a major focus of the [semiconductor] industry” as enabling chip technology and the electrification of devices and platforms become ubiquitous.

Bottom line:

The societal benefits of semiconductor technologies are quickly being overshadowed by the climate consequences. The chip industry understands it must change. Achieving Net Zero goals by 2050 may be too late. A crash program is needed. Chip makers with foresight and the wisdom to seize the first-mover advantage on sustainability are sure to prosper. Future generations will thank them.

George Leopold, a frequent contributor to the Ojo-Yoshida Report, is the author of Calculated Risk: The Supersonic Life and Times of Gus Grissom.

Copyright permission/reprint service of a full TechSplicit story is available for promotional use on your website, marketing materials and social media promotions. Please send us an email at [email protected] for details.