The Fab Challenge

Tough Questions for Intel CEO and Its Board

Podcast: The CHIPS Act and How Best to Spend $52B

Enlisting the Semiconductor Army

Beware the Semiconductor 'Bullwhip Effect'

CHIPS Act: Opening a Pipeline for New Engineers

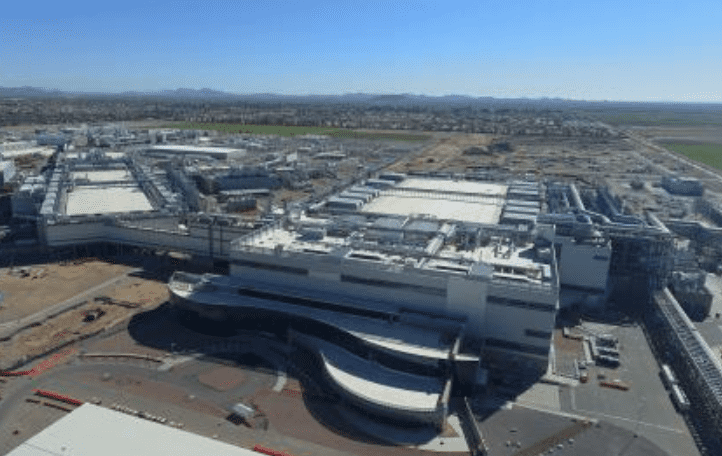

So You Want to Build a Fab

Tough Questions for Intel CEO and Its Board

By Bolaji Ojo

If Intel Corp. is to successfully complete its promised $200 billion-plus fab investment over the next decade it will need more than the $10 billion to $15 billion in seed funding analysts expect it to receive from the U.S. CHIPS Act passed recently by Congress.

Podcast: The CHIPS Act and How Best to Spend $52B

After two years of legislative maneuvering, the U.S. Congress at last acted in late July to strengthen American technology supply chains with passage of the $280 billion Chips and Science Act.

Enlisting the Semiconductor Army

What’s at stake?

Unfilled positions at U.S. fabs will soon exceed 100,000 engineers and technicians. The labor shortfall has prompted a growing number of chipmakers and equipment vendors to focus their recruiting efforts on military veterans. The challenge is translating skills learned on the battlefield to the factory floor.

Beware the Semiconductor 'Bullwhip Effect'

By Peter Clarke

Over the last few years, with strong IC demand exceeding supply, wafer fab operators have put the pedal to the metal with major capital expenditures.

CHIPS Act: Opening a Pipeline for New Engineers

What’s at stake?

The CHIPS Act has become law, fueled by the political will to shore up America’s manufacturing and technological edge to counter China. The pandemic-induced global chip shortage helped generate bipartisan support for the new legislation as both government and industry came to the realization that decades of offshoring might have been a mistake. But ultimately, the CHIPS Act will be deemed successful only if it broadens the pipeline of U.S.-educated EEs who are trained and ready to step into jobs at the promised domestic facilities.

So You Want to Build a Fab

By Ron Wilson

What’s at stake?

Talking about building new fabs is easy and politically savvy. But the logistics of financing, constructing, equipping, staffing and operating a modern chip foundry are fraught with peril.